CORSON (C19010, C7025, C7026, MAX126)

Characteristic:

Corson is a highly relilable and high performance copper alloy, In particular, temperature aging is applied. This effect is like re-calendering, which makes the material more rigid and strong, while increasing conductivity and elongation.

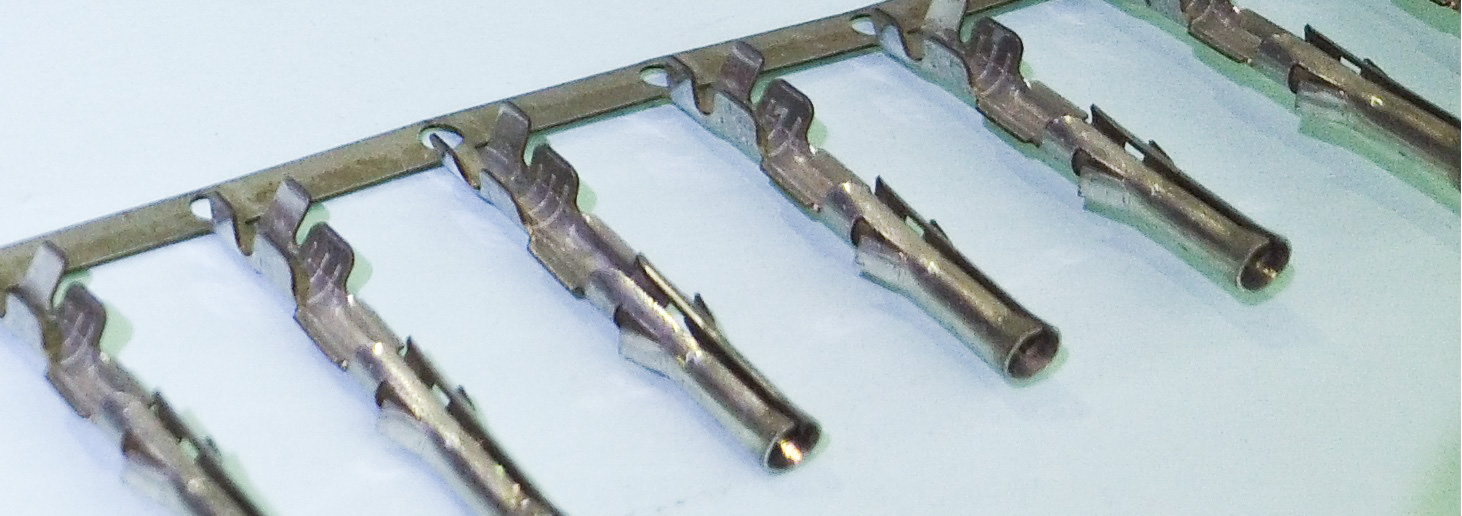

Application:

It can be applied to electrical connection parts in both signal and power. It is also suitable for automotive terminals, connector and IC lead frame materials on smart phone. Corson is often electroplated in connector applications.

Special Copper Alloy (C50715, 50710)

Characteristic:

Having high strength and good workability, high heat resistance temper and easy plating.

Application:

Automobile terminals,electrical terminals.

Tin Brass C4250

Characteristic:

Mechanical strength is higher than Brass C2600 and close to phosphor bronze C5191. and Conductivity is higher than C5191. C4250 also have good heat resistance.

Application:

Applied to Automobile terminals.

| Alloy No | Chemical Composition(%) | Electrical Conductivity-IACS | Temper | Vickers Hardness | Tension Strength (N/mm²) |

Elongation (%) | Download |

|---|---|---|---|---|---|---|---|

| C19210 | Cu≧99.60 Fe:0.05~0.15 P:0.025~0.04 |

≧85 | O | ≦90 | 255~335 | ≧30 |

Download |

| 1/4H | 90~115 | 275~355 | ≧20 | ||||

| 1/2H | 100~125 | 295~375 | ≧10 | ||||

| 3/4H | -- | -- | -- | ||||

| H | 110~135 | 330~415 | ≧5 | ||||

| EH | ≧115 | ≧370 | -- | ||||

| SH | -- | -- | -- | ||||

| ESH | -- | -- | -- | ||||

| C194 | Cu≧97.0 Fe:2.1~2.6 P:0.015~0.15 Zn:0.05~0.2 |

≧60 | O | 90~110 | 310~380 | ≧25 |

Download |

| 1/4H | -- | -- | -- | ||||

| 1/2H | 110~130 | 365`435 | ≧5 | ||||

| 3/4H | -- | -- | -- | ||||

| H | 125~145 | 410~485 | ≧2 | ||||

| EH | 135~150 | 460~505 | -- | ||||

| SH | 140~155 | 480~525 | -- | ||||

| ESH | ≧145 | 500~550 | -- | ||||

| C1441 | Sn:0.1~0.2 P:0.03~0.024 Fe≦0.02 Cu:Rem |

≧80 | O | ≦70 | 195~245 | ≧35 |

Download |

| 1/4H | 65~100 | 215~295 | ≧25 | ||||

| 1/2H | 80~110 | 255~335 | ≧15 | ||||

| 3/4H | -- | -- | -- | ||||

| H | 95~125 | 315~395 | ≧5 | ||||

| EH | ≧110 | ≧370 | ≧2 | ||||

| SH | -- | -- | -- | ||||

| ESH | -- | -- | -- | ||||

| C14415 | Cu+Sn≧99.96 Sn:0.1~0.15 |

≧90 | O | ≦70 | 195~245 | ≧35 |

Download |

| 1/4H | 65~100 | 215~295 | ≧25 | ||||

| 1/2H | 80~110 | 255~335 | ≧15 | ||||

| 3/4H | -- | -- | -- | ||||

| H | 100~125 | 315~395 | ≧5 | ||||

| EH | 120~145 | 385~460 | ≧2 | ||||

| SH | 130~150 | 450~510 | -- | ||||

| ESH | ≧140 | ≧490 | -- | ||||

| C1814 | Cr:0.15~0.45 Zr:0.05~0.25 Si:0.005~0.05 Cu:Rem |

≧80 | O | -- | -- | -- |

Download |

| 1/4H | -- | -- | -- | ||||

| 1/2H | 135~160 | 470~550 | ≧6 | ||||

| 3/4H | -- | -- | -- | ||||

| H | 145~170 | 510~590 | ≧3 | ||||

| EH | -- | -- | -- | ||||

| SH | ≧165 | ≧540 | -- | ||||

| ESH | -- | -- | -- | ||||

| C19010 | Ni:0.8~1.8 Si:0.15~0.35 P:0.01~0.05 Zn≦0.5 Sn≦0.15 Cu:Rem |

≧55 | O | -- | -- | -- |

Download |

| 1/4H | 100~130 | 360~430 | ≧12 | ||||

| 1/2H | 120~155 | 410~470 | ≧10 | ||||

| 3/4H | -- | -- | -- | ||||

| H | 135~165 | 460~520 | ≧8 | ||||

| EH | 145~175 | 520~590 | ≧7 | ||||

| SH | 170~200 | ≧580 | ≧6 | ||||

| ESH | -- | -- | -- | ||||

| C7025 | Ni:2.2~4.2 Si:0.25~1.2 Mg:0.05~0.3 Cu:Rem |

≧40 | O | 180~210 | 620~755 | ≧10 |

Download |

| 1/4H | -- | -- | -- | ||||

| 1/2H | 200~230 | 655~825 | ≧7 | ||||

| 3/4H | 220~250 | 685~860 | ≧5 | ||||

| H | 240~270 | 795~900 | ≧1 | ||||

| EH | -- | -- | -- | ||||

| SH | -- | -- | -- | ||||

| ESH | -- | -- | -- | ||||

| C7026 | Ni:1.0~3.0 Si:0.2~0.7 Cu:Rem |

≧40 | O | 170~200 | 590~655 | ≧25 |

|

| 1/4H | -- | -- | -- | ||||

| 1/2H | 190~220 | 675~745 | ≧7 | ||||

| 3/4H | 210~240 | 725~795 | ≧5 | ||||

| H | 230~260 | 755~835 | ≧1 | ||||

| EH | -- | -- | -- | ||||

| SH | -- | -- | -- | ||||

| ESH | -- | -- | -- |

*Electrical conductivity is the annealing value